Sprayball

Main Menu

Copyright © 2016 - HAKE GmbH. All Rights Reserved.

Stationary HAKE spray balls offer the following advantages over rotating spray balls:

•

No moving parts, therefore no charges for maintenance and repair

•

Easy mounting at the connection piece by means of non-obstructing clamp which allows self-cleaning of the

connection piece and convenient dismounting in case of choking.

•

Careful laser-processing of the drillings enables a well concentrated guidance of the water jet over a wide

range without bursts or spatter.

•

Sensible layout of the drillings and the means of mounting make the spray-balls self-cleaning. No residue can

get in the dead corner of the connection piece.

•

Flawless operation, even with the pump at low pressure.

•

Made from corrosion-proof chrome nickel steel, PTFE on request.

•

Tanks with complicated internal installations can be cleaned by corresponding placement of multiple spray

balls.

Typical application of our spray balls include many business areas, e.g. food processing and beverage as well as the

chemical industry, in breweries and dairies etc. HAKE spray balls are offered worldwide by our local distributors in

Switzerland, the Netherlands, New Zealand, USA and Denmark. Further local distributions are under construction.

Modern technology strives for targets which can only be realised by the joined effort of the producers of machinery

and the suppliers. Our close collaboration with the manufacturing industry enables us to present offers which

resemble the latest state of the art. Our aim is an increase in economic efficiency and rationalization while

considering the aspect of quality and expenses. In case a custom installation and special application is required, do

not hesitate to ask us, the producer.

Sprayballs

Satisfaction of our customers

is our duty and our driving force.

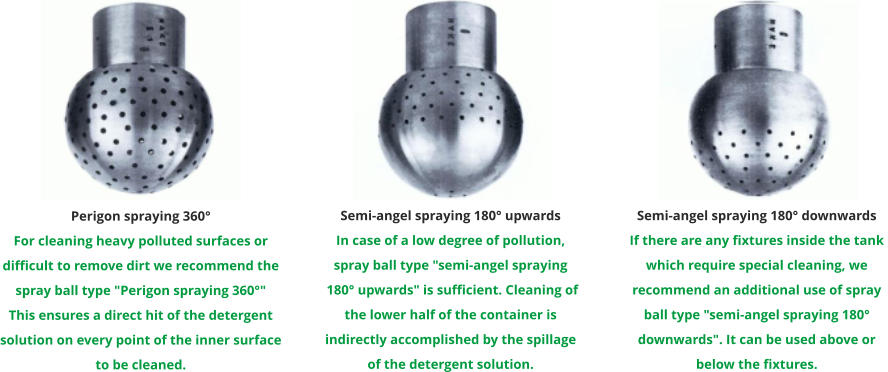

Based on our knowledge in manufacturing low pressure spray balls we are successful partners of our customers for more than 35 years. Expert knowledge, experience and engagement made us competent partners for our customers right from the beginning. The spray ball with the pin-symbol for all existing containers, tanks, tubs, vats, etc. from nominal diameter 8 - 50mm (0.32-1.97inch). Fixed installation of static low pressure spray balls is today’s prime technical solution for spraying disinfectants or detergent solutions. The low pressure range lies between 0,5bar (72.5lb/in2) and 10bar (1450(lb/in2). This pressure range is often found in working environments. Following conditions must be met for a flawless operation of the low pressure cleaning: 1. The walls of the containers (including any fixtures inside the tank) have to be sprayed evenly with the detergent solution. 2. The flushing of the walls needs to be of a certain intensity to achieve appropriate flow conditions on the walls. 3. he spray balls guarantee a maximum of operational reliability, especially non rotating spray balls. Fixed installed spray balls have to be self cleaning, because they can be submerged in the distributed medium after the container is filled. 4. Cleaning periods should be kept as short as possible. This is achieved by employing suitable chemicals, an appropriate temperature and a corresponding type of spray ball.

Copyright © 2016 - HAKE GmbH. All Rights Reserved.

Sprayballs

Satisfaction of our customers

is our duty and our driving force.

Based on our knowledge in manufacturing low pressure spray balls we are successful partners of our customers for more than 35 years. Expert knowledge, experience and engagement made us competent partners for our customers right from the beginning. The spray ball with the pin-symbol for all existing containers, tanks, tubs, vats, etc. from nominal diameter 8 - 50mm (0.32-1.97inch). Fixed installation of static low pressure spray balls is today’s prime technical solution for spraying disinfectants or detergent solutions. The low pressure range lies between 0,5bar (72.5lb/in2) and 10bar (1450(lb/in2). This pressure range is often found in working environments. Following conditions must be met for a flawless operation of the low pressure cleaning: 1. The walls of the containers (including any fixtures inside the tank) have to be sprayed evenly with the detergent solution. 2. The flushing of the walls needs to be of a certain intensity to achieve appropriate flow conditions on the walls. 3. he spray balls guarantee a maximum of operational reliability, especially non rotating spray balls. Fixed installed spray balls have to be self cleaning, because they can be submerged in the distributed medium after the container is filled. 4. Cleaning periods should be kept as short as possible. This is achieved by employing suitable chemicals, an appropriate temperature and a corresponding type of spray ball.

Stationary HAKE spray balls offer the following

advantages over rotating spray balls:

•

No moving parts, therefore no charges for maintenance and

repair

•

Easy mounting at the connection piece by means of non-

obstructing clamp which allows self-cleaning of the connection

piece and convenient dismounting in case of choking.

•

Careful laser-processing of the drillings enables a well

concentrated guidance of the water jet over a wide range without

bursts or spatter.

•

Sensible layout of the drillings and the means of mounting make

the spray-balls self-cleaning. No residue can get in the dead

corner of the connection piece.

•

Flawless operation, even with the pump at low pressure.

•

Made from corrosion-proof chrome nickel steel, PTFE on request.

•

Tanks with complicated internal installations can be cleaned by

corresponding placement of multiple spray balls.

Typical application of our spray balls include many business areas, e.g.

food processing and beverage as well as the chemical industry, in

breweries and dairies etc. HAKE spray balls are offered worldwide by

our local distributors in Switzerland, the Netherlands, New Zealand,

USA and Denmark. Further local distributions are under construction.

Modern technology strives for targets which can only be realised by the

joined effort of the producers of machinery and the suppliers. Our

close collaboration with the manufacturing industry enables us to

present offers which resemble the latest state of the art. Our aim is an

increase in economic efficiency and rationalization while considering

the aspect of quality and expenses. In case a custom installation and

special application is required, do not hesitate to ask us, the producer.